Our products:

Articles

FAQ

Efficiency:

104,4%

Output:

12 kW

INTERFIRE 11

Condensation

This technique relates to use not only the heat that arises during combustion as a measurable temperature of exhaust gases, but also steam content in fuel gases. InterFire branded condensing boilers are able to use almost all heat contained in the exhaust gases and transform them for heating.

EcoDesign

EcoDesign 2020 Directive laid down restrictive requirements regarding emission and efficiency what is reflected in boiler actual use during the heating season.

5 Class

All boilers have been tested by an independent institute with EU notification to ensure reliable results that are recognized all over the world.

BAFA

Our Company is the only Polish manufacturer whose all pellet fired boilers are listed by BAFA what proves the highest quality and conformity with requirements regarding emission.

5-year guarantee

High-quality materials and modern technologies used in production allow us to extend the warranty on the tightness of the boiler up to 5 years.

Lambda probe

Smart logarithm controls boiler operation according to current ambient conditions, and ensures the highest possible efficiency. It guarantees maximum reduction of emission and soot deposits.

Condensation efficiency

Low fume temperature, optimal combustion parameters thanks to lambda probe and condensation ensure 104.4% efficiency of InterFire boiler.

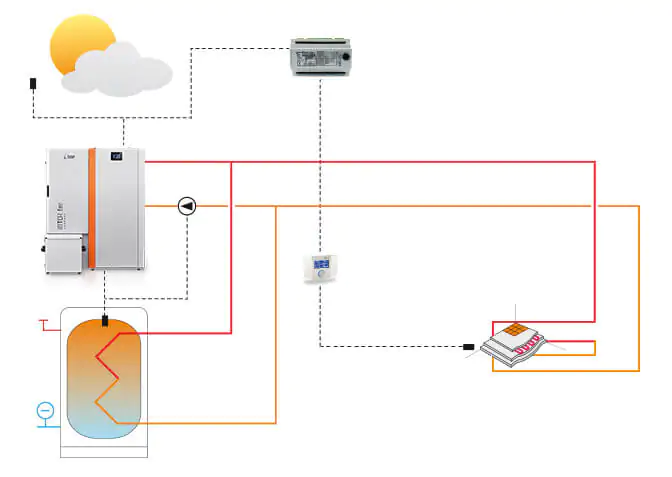

Wide outlet temperature range (20-85oC)

Stainless steel heat exchanger provided in HCC (Heat-Cold Cassette) system enables boiler operation at inlet temperature as low as 20oC. Therefore InterFire boiler is a perfect solution for housebuilding industry and low temperature heating systems namely under floor heating systems.

Simple installation

InterFire boiler does not require protection from cold water coming back from installation which makes the installation easier and cheaper comparing to traditional solid fuel boilers.

Mechanical burner cleaning

The grate driven by the actuator ensures automatic cleaning of burner before firing up and after shut down what ensures high comfort during boiler operation, as well as high efficiency and conformity with environmental requirements.

Compact design

Small size allows for installation in any boiler room.

Touch screen

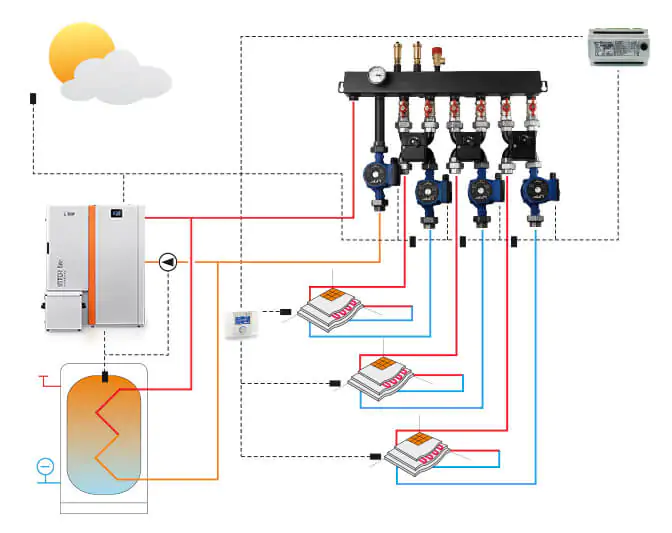

Thanks to user-friendly controller that in standard version drives operation of 2 heating circuits (extension is possible up to 4 circuits optionally), buffer, temperature thermostat, lambda probe (optionally).

Stainless steel

High quality materials used for burner manufacture ensure long-time performance, whereas specially designed construction ensures optimal pellet combustion.

Automatic cleaning

Burner and exchanger automatic cleaning ensures comfort and high efficiency during operation.

Rotary valve

Rotary valve that protects the fuel in the pellet tank against fire.

Energy savings

Energy-efficient components that reduce energy consumption and save your money.

An advanced controller

User-friendly touch screen, provision of hot domestic water in standard and possible extension with: 4 circuits, buffer, temperature thermostat, lambda probe.

Internet

An advanced ecoNET300 communication module ensures remote boiler operation, servicing, overview of parameters history, as well as sending e-mail messages and alarms.

Automatic ash removal

Automatic ash removal system ensures ash collection inside the container where compressing follows. Therefore the user removes the ash no sooner that after some months.

A+

INTERFIRE 11

An advanced controller controls boiler operation and boiler room system including pumps, valves, actuators, buffers and the boiler. This way all the devices make for an integrated system to ensure optimal performance.

Pneumatic pellet supply from a big dispenser. Available optionally

INTERFIRE 11

Output: 12 kW

Material:

Stainless steel

Feeder:

Screw feeder, rotary valve

Burner:

Burner, automatic igniter, automatic burner cleaning system

Controller:

Lambda probe, output control, temperature thermostat, 2 heating circuits (+2 circuits optionally), 1 hot water circuit, Internet WiFi (optionally), remote control (optionally)

Heat exchanger cleaning:

Automatic

Fuel:

Pellets

Condensation efficiency:

104,4%

Heat exchanger:

HCC (Heat-Cold Cassette), stainless steel

Dispenser volume:

150 / 240 / 400 l

Fuel supply system:

Optionally with VACUUM fuel pneumatic supply system

INTERFIRE 11

Technical Data

| Model | IF11 | |

|---|---|---|

| Nominal output: | kW | 12,0 |

| Thermal power range: | kW | 3,6 ÷ 12,0 |

| Condensation efficiency: Granulated pellets Q=18 MJ/kg |

% | 104,4 |

Dimensions

| Model | IF11 / 150L | IF11 / 240L | IF11 / 400L | |

|---|---|---|---|---|

| Height: | mm | 1480 | 1480 | 1480 |

| Width: | mm | 1040 | 1250 | 1480 |

| Depth: | mm | 885 | 885 | 885 |

INTERFIRE 11

Modern heating devices

Articles

FAQ